A Cold Chain Imperative

As dawn breaks over California’s Central Valley, crates of ripe strawberries begin a 2,800-mile journey to New York supermarkets. Their survival hinges on a marvel of mobile thermodynamics: the refrigerated truck. Unlike standard cargo trucks transporting inert goods, these temperature-controlled vehicles function as moving microclimates, preserving perishables from farm to fork through precision engineering that combats heat infiltration, humidity fluctuations, and microbial growth with relentless efficiency.

1. Core Architecture: Insulation & Refrigeration Synergy

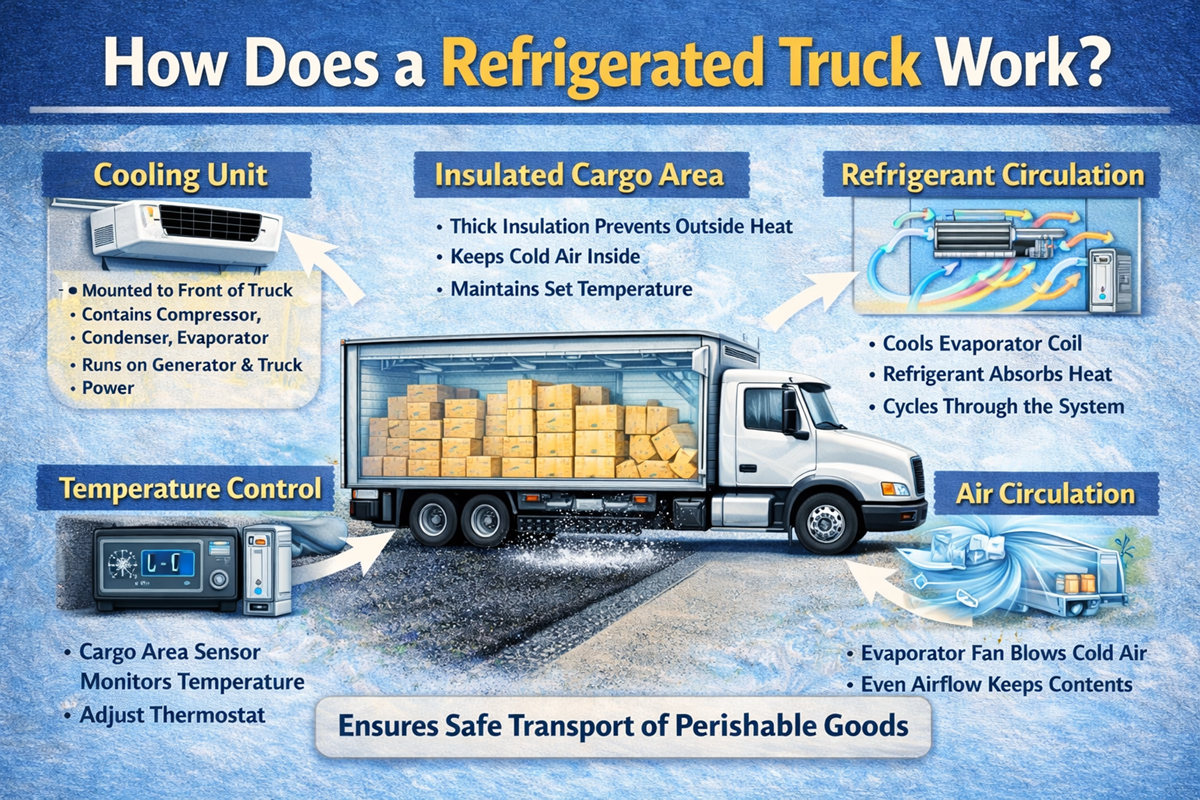

The refrigerated trailer’s effectiveness stems from three integrated subsystems working in concert.

Thermal Barrier Engineering

- Composite Wall Construction: 60-80mm panels fuse polyurethane foam (R-value 7.2–8.5 per inch) with fiberglass-reinforced exteriors, limiting heat transfer to 0.12–0.15 W/m²K – outperforming residential insulation by 300%.

- Hermetic Sealing: Laser-aligned door gaskets and floor channels maintain airtight integrity, reducing ambient air infiltration to under 1.5% of total volume/hour during transit.

Refrigeration Unit Mechanics

- Vapor-Compression Cycle: Diesel-powered (or electric standby) compressors pressurize R-452A refrigerant into 120°F superheated gas, which condenses in condenser coils, releasing ambient heat before expanding through valves into evaporator coils at -20°F.

- Evaporator Innovation: Microchannel aluminum fins increase surface area 400% versus tube-and-fin designs, accelerating heat absorption from cargo air while minimizing frost buildup.

2. Climate Intelligence: Sensors & Control Systems

Modern units transcend simple cooling with reactive environmental management.

Precision Thermoregulation

- Multi-Zone Monitoring: Strategically placed PT1000 RTD sensors track temperatures at floor, ceiling, and door zones with ±0.2°C accuracy, triggering localized compressor adjustments before hot spots develop.

- Adaptive Defrosting: Microprocessor-controlled cycles inject hot refrigerant into evaporator coils only when ice sensors detect >3mm buildup – reducing energy waste by 35% versus timed defrosts.

Atmosphere Control

- Ethylene Scrubbers: Activated carbon/Potassium permanganate filters remove ripening gases from produce loads, extending strawberry shelf life by 40%.

- Humidity Management: Desiccant wheels or mist systems maintain 85–95% RH for leafy greens versus 60–70% RH for pharmaceuticals – all programmable via touchscreen interfaces.

3. Power Dynamics: Energy Sources & Efficiency

Balancing cooling demand with operational constraints requires innovative power solutions.

Drive vs. Standby Systems

- Direct-Drive Units: Powered by the truck’s engine via PTO shafts during transit (consuming 3–5 gallons of diesel/hour), seamlessly switching to electric standby (480V 3-phase) at distribution centers to avoid idling emissions.

- Hybrid Advancements: Lithium-ion battery banks recharge during highway operation, enabling 4–8 hours of emission-free cooling for urban deliveries under increasing zero-emission zone regulations.

Energy Recovery Technologies

- Waste Heat Utilization: Captured compressor exhaust preheats refrigerant in economizer circuits, lowering fuel consumption by 18–22% during pulldown phases.

4. Specialized Configurations: Beyond Universal Cooling

Payload diversity demands tailored thermal strategies.

Multi-Temperature Zoning

- Triple-Compartment Trailers: Segregated sections with independent evaporators simultaneously maintain frozen (-18°C), chilled (0–4°C), and ambient (15°C) environments using internal bulkheads with 10+ R-value insulation.

Cryogenic & CA Systems

- Liquid Nitrogen Injection: For ultra-rapid chilling (-60°C), vaporizing LN₂ displaces oxygen while cooling, creating temporary controlled atmospheres ideal for seafood transport.

- Dynamic CA (Controlled Atmosphere): Oxygen sensors and nitrogen generators suppress respiration in apple shipments, reducing O₂ to 1–2% to extend preservation by months.

5. Operational Integrity: Challenges & Fail-Safes

Maintaining cargo viability requires anticipating systemic vulnerabilities.

Thermal Bridging Mitigation

- Composite Flooring: Fiber-reinforced polymer decks with thermal breaks eliminate conductive heat transfer from road surfaces that traditional steel floors permit.

- Door Curtain Systems: Rapid-roll PVC barriers retain cold air during 30-second dock unloading, preventing the 15–20°F spikes common with open doors.

Remote Telemetry & Redundancy

- Satellite Monitoring: 5G-enabled IoT systems transmit real-time temperature/humidity data to fleet managers, triggering SMS alerts if parameters deviate.

- Backup Vapor Systems: Secondary refrigerant circuits automatically engage during compressor failure, maintaining temperatures for 6+ hours – critical for vaccine transport.

The Cold Chain Linchpin

While dump trucks dominate aggregate hauling and standard cargo trucks navigate dry freight lanes, the refrigerated trailer operates as a climate-controlled fortress on wheels. Its capacity to sustain biological stability across continents separates it fundamentally from all-purpose Vantrucktrailer configurations. In a world where 40% of food spoils in transit and pharmaceuticals demand uncompromising thermal integrity, this mobile refrigeration ecosystem doesn’t merely transport goods – it engineers time, bending spoilage curves through meticulously managed entropy to deliver vitality intact.