Introduction: The Unsung Hero of Infrastructure

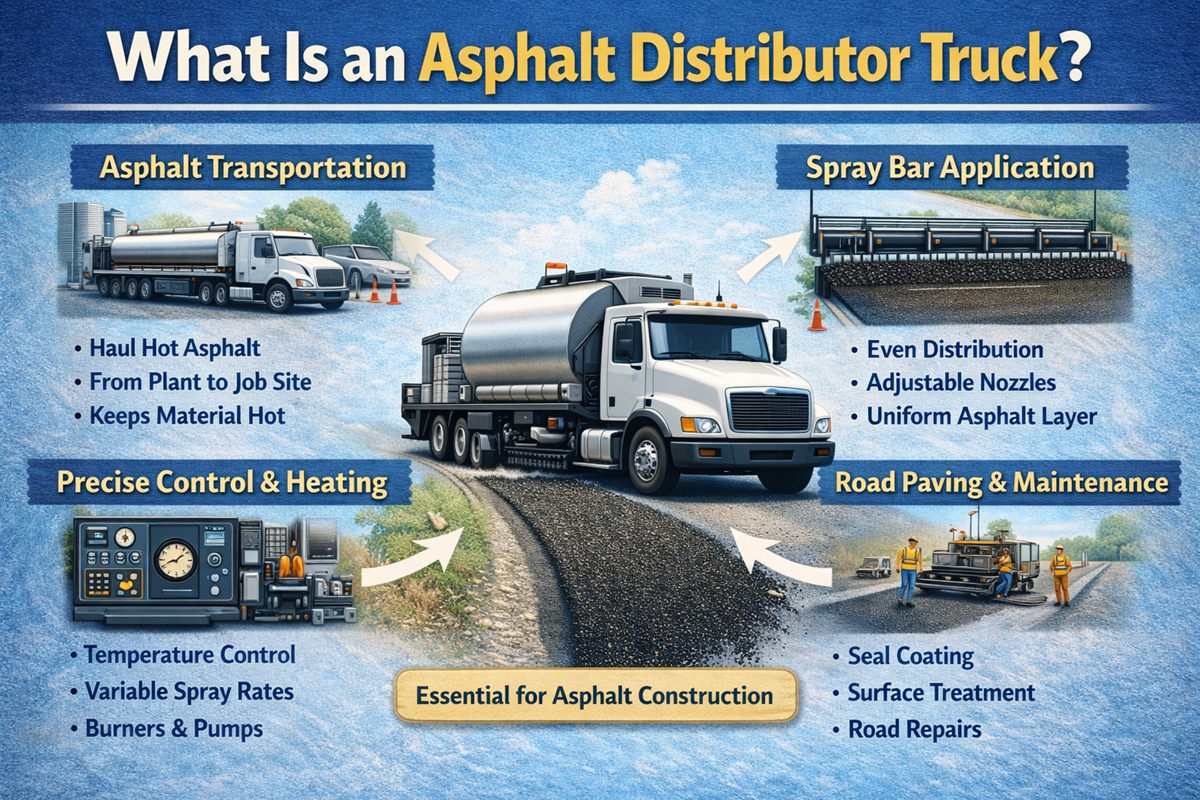

On this Tuesday afternoon, as commuters navigate freshly paved highways, few consider the machinery enabling smooth, durable roads. Among these specialized assets, the asphalt distributor truck operates with surgical precision—far beyond the capabilities of standard cargo trucks or dump trucks. This vehicle is not merely a transporter but a mobile factory, ensuring the foundational layers of modern infrastructure adhere flawlessly.

1. Core Functionality: Anatomy of a Distributor Truck

Distinguishing itself from conventional haulers, an asphalt distributor integrates three critical subsystems:

Thermal Management & Storage

- Insulated Tanks: Constructed with double-walled stainless steel, these maintain asphalt binders (including cutbacks and emulsions) at 150–190°C, preventing premature cooling and viscosity changes.

- Agitation Systems: Internal paddles or jet circulation combat material stratification, ensuring homogeneous consistency for uniform application.

Precision Spray Systems

- Computerized Bar Controls: GPS-guided spray bars with individually programmable nozzles adjust application rates (0.05–2.0 gal/yd²) in real-time, accommodating variable road geometries.

- Pressure Regulation: Hydraulic pumps deliver consistent 40–100 PSI outputs, atomizing viscous asphalt into optimal droplet sizes for adhesion.

2. Critical Applications: Beyond Surface Treatment

Distributors enable multiple construction methodologies, each demanding exact binder deployment:

Tack Coating: The Molecular Adhesive

- Interface Bonding: Spraying emulsified asphalt between pavement layers creates a waterproof seal and boosts shear resistance by 300–400%, preventing delamination under traffic loads.

Chip Sealing & Surface Dressing

- Aggregate Synchronization: Distributors coordinate with aggregate spreaders, applying binder milliseconds before stone chips embed—reducing curing time by 70% versus manual methods.

3. Engineering Innovations: From Combustion to Automation

Modern units transcend basic spraying with integrated technologies:

Intelligent Heat Exchange

- Direct-Fire Burners: Diesel-powered burners with 2.5M BTU/hour output rapidly heat cold material, while thermal oil systems prevent overheating degradation in polymers like SBS-modified asphalt.

Data-Driven Operation

- Telematics Integration: Onboard sensors log spray volume, temperature, and coverage maps, generating compliance reports for DOT specifications (e.g., AASHTO T40).

4. Operational Versatility: Adapting to Global Standards

From rural access roads to airport runways, distributors adjust to diverse requirements:

Variable Configuration Capabilities

- Modular Tank Sizes: Ranging from 500–5,000-gallon capacities, supporting everything from pothole patching to interstate resurfacing.

- Specialized Spray Patterns: Adjustable bars handle widths from 4 ft (shoulder repairs) to 28 ft (multi-lane highways), with oscillating nozzles for curbs and contours.

5. Strategic Value: Cost Efficiency & Long-Term Performance

Investing in dedicated distributors yields exponential returns across the infrastructure lifecycle:

Lifecycle Economics

- Material Optimization: Precision spraying reduces binder waste by 15–22% compared to manual application, saving 8K–12K per project.

- Durability Multiplier: Proper tack coats extend pavement service life by 8–12 years, slashing rehabilitation costs by 40%.

Sustainability Integration

- Low-Emission Models: Tier 4 Final engines and electric burner options cut particulate emissions by 90%, aligning with EPA’s Clean Air Act benchmarks.

The Distribution Imperative

While dump trucks move aggregate and cargo trucks deliver supplies, the distributor truck transforms raw materials into engineered surfaces. Its ability to precisely place temperature-sensitive binders at calculated rates remains irreplaceable—whether deploying polymer-modified asphalt for an airport runway or rejuvenating a suburban avenue. This machine exemplifies how specialized equipment elevates outcomes: No Vantrucktrailer conversion or general hauler can replicate its calibrated fusion of thermal control, hydraulic precision, and data analytics. In an era demanding resilient, sustainable infrastructure, the asphalt distributor isn’t just a vehicle—it’s the cornerstone of enduring mobility.