In the high-stakes world of temperature-controlled logistics, efficiency isn’t merely a cost-saving measure – it’s the bedrock of product integrity, regulatory compliance, and competitive advantage. As fuel prices fluctuate and sustainability mandates tighten, operators of refrigerated trucks face relentless pressure to optimize every facet of their cold chain operations. While robust refrigeration units are fundamental, the true frontier of optimization lies in strategic technological upgrades that work synergistically to minimize energy consumption, slash operational costs, ensure unwavering temperature consistency, and extend equipment lifespan. Embracing these innovations transforms a standard reefer unit from a simple cargo chiller into a sophisticated, data-driven asset capable of navigating the complexities of modern perishable goods transport. The journey towards peak efficiency demands a holistic approach, integrating advancements in monitoring, insulation, refrigeration hardware, power management, aerodynamics, and intelligent automation to create a seamlessly functioning cold chain ecosystem resilient against external pressures and internal inefficiencies.

Intelligent Oversight: Telematics & Advanced Monitoring Systems

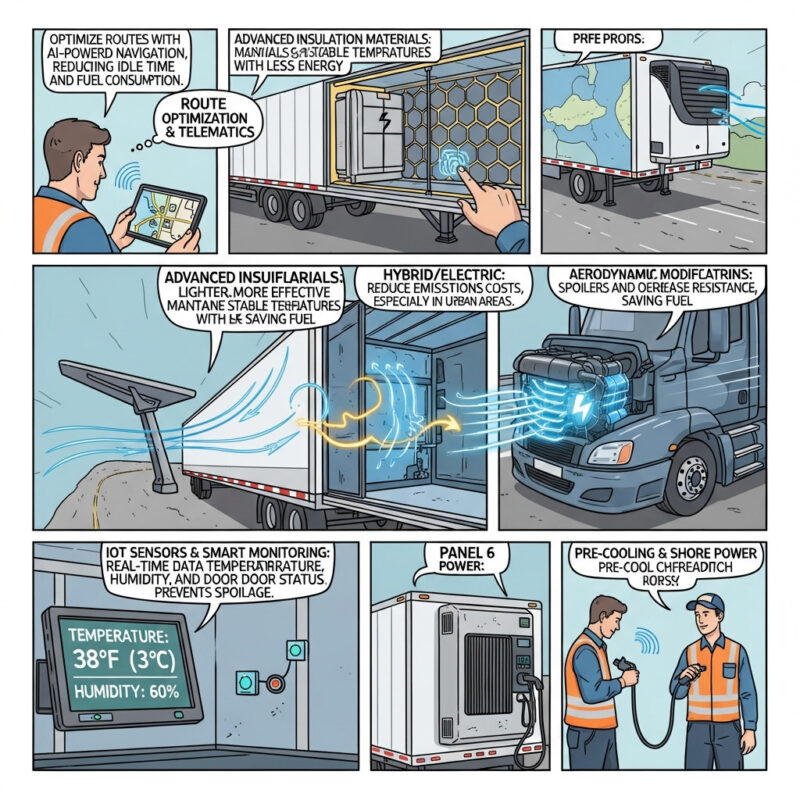

The cornerstone of modern refrigerated truck efficiency is comprehensive, real-time visibility. Sophisticated telematics systems have evolved far beyond basic GPS tracking, becoming indispensable neural networks for the cold chain.

- Real-Time Monitoring & Alerts: Modern sensors provide continuous, granular data on cargo space temperature and humidity at multiple points (not just the return air), door-open events, fuel levels, engine status, and precise geo-location. Cloud-connected platforms instantly relay this data to fleet managers and drivers, triggering immediate alerts for any deviation from preset parameters. This enables rapid corrective action before product spoilage occurs, safeguarding valuable pharmaceutical, floral, or food shipments and preventing costly rejections or claims. Advanced systems even track the duration and location of each door opening, identifying potential procedural inefficiencies.

- Predictive Maintenance & Performance Analytics: Telematics harness predictive analytics to move beyond reactive repairs. By continuously monitoring compressor cycles, engine load profiles, fuel consumption patterns relative to ambient temperature, and component vibration signatures, these systems can forecast potential failures – such as a weakening compressor clutch or deteriorating door seals – with remarkable accuracy. This allows maintenance to be scheduled proactively during planned downtime, preventing costly roadside breakdowns, emergency repairs, and the catastrophic temperature excursions they cause. Furthermore, deep analytics reveal trends in unit performance, identifying trucks or trailers consuming excess fuel due to suboptimal settings or emerging mechanical issues, enabling targeted interventions.

Containing the Cold: Next-Generation Insulation & Sealing Technologies

The most efficient refrigeration unit struggles if the cargo box itself leaks cold air. Cutting-edge materials and designs are revolutionizing thermal retention.

- Advanced Insulation Materials: Traditional polyurethane foam remains common, but its performance is being surpassed. Vacuum Insulated Panels (VIPs), though currently higher cost, offer up to ten times the insulating value (R-value) per inch compared to standard foam, enabling thinner walls for increased payload capacity or vastly improved thermal efficiency in standard dimensions. Aerogel composites are also emerging, providing exceptional insulation with minimal thickness and weight. Even advanced foam formulations utilizing nano-additives or optimized cell structures are pushing thermal efficiency boundaries for standard applications, significantly reducing the thermal load the refrigeration unit must overcome.

- Superior Sealing Solutions: Heat ingress through door seals and body joints is a major culprit. Advanced magnetic sealing gaskets create a vastly more consistent and airtight closure than traditional bulb seals, especially critical on frequently opened delivery van truck bodies. Thermally broken structural components minimize conductive heat transfer through the frame itself. Automated dock shelter systems create a near-hermetic seal between the truck and warehouse dock, preventing ambient air influx during loading/unloading – a period of significant thermal vulnerability often overlooked in efficiency calculations.

The Heart of Efficiency: High-Performance Refrigeration Unit Upgrades

Modernizing the refrigeration unit itself delivers dramatic efficiency leaps through intelligent component design and control.

- Variable Speed Compressors & Fans: Replacing fixed-speed components with variable speed technology is arguably the single most impactful upgrade. Compressors that can modulate their speed precisely match cooling capacity to the actual thermal load in real-time, eliminating the energy-wasting cycle of constant on/off operation. Similarly, EC (Electronically Commutated) evaporator and condenser fans adjust airflow dynamically based on need, consuming a fraction of the power of traditional AC fans. This modulation significantly reduces fuel consumption (or battery drain) and minimizes wear and tear on components.

- Hybrid Drive & Electric Standby Systems: Hybrid drive units combine a smaller diesel engine with an electric motor powered by an integrated battery pack. The system intelligently switches between or combines power sources, optimizing for fuel efficiency, especially during idling or low-load conditions prevalent in multi-stop delivery routes common for smaller cargo truck applications. Electric standby capability allows the unit to plug into shore power at depots or during extended stops, eliminating diesel consumption, noise, and emissions entirely during these periods – a crucial feature for urban deliveries and overnight parking.

- Advanced Defrost Systems: Traditional timed defrost cycles waste energy by heating evaporator coils unnecessarily. Demand defrost systems utilize sensors to initiate defrost only when actual frost buildup is detected, significantly reducing energy use. Hot gas defrost methods, which utilize waste heat from the refrigeration cycle itself, are far more energy-efficient than traditional electric heater defrost systems.

Powering the Chill: Auxiliary Power & Energy Harvesting

Keeping the cold chain running without excessive main engine idling requires smart auxiliary power solutions and innovative energy sourcing.

- Advanced Auxiliary Power Units (APUs): Modern diesel APUs are vastly more fuel-efficient and quieter than idling the main truck engine solely to power the reefer unit. They provide essential power for refrigeration, cab heating/cooling, and electronic devices. Battery Electric APUs (BE-APUs) store energy from various sources (regenerative braking, shore power) to provide silent, zero-emission power for the refrigeration unit and cab amenities during rest periods, crucial for compliance with strict anti-idling regulations in urban centers and reducing overall fuel costs.

- Solar Photovoltaic (PV) Integration: Installing solar photovoltaic panels on the trailer or truck roof is a rapidly growing solution. These panels continuously harvest solar energy to trickle-charge the refrigeration unit’s battery bank or directly supplement its power needs. While not typically sufficient to run the unit alone under high load, solar significantly reduces the runtime of diesel-powered components (genset, APU, or main engine), extending battery life, cutting fuel costs by 5-15% or more annually, and reducing carbon emissions. This is particularly effective for trailers parked in sunny yards or during daytime transit.

Slicing Through the Air: Aerodynamic Optimizations

Reducing the drag of the refrigerated unit and trailer directly translates to lower fuel consumption for the entire vehicle.

- Reefer-Specific Fairings & Skirts: While tractor aerodynamics are well-known, optimizing the refrigerated trailer itself is critical. Gap fairings streamline the turbulent space between tractor cab and trailer. Side skirts dramatically reduce under-trailer drag. Critically, reefer-specific nose fairings are designed to integrate with the protruding refrigeration unit smoothly, mitigating the significant aerodynamic penalty caused by its boxy shape disrupting airflow over the trailer front. These components collectively contribute to measurable fuel savings, especially at highway speeds.

- Low-Rolling Resistance Tires: Specifying low-rolling resistance tires for both tractors and trailers reduces the energy required to move the vehicle. When combined with proper tire pressure monitoring systems (TPMS) ensuring optimal inflation, the cumulative effect on fuel efficiency for a temperature-controlled fleet is substantial.

Automating Precision: Smart Control Systems & AI

The future of efficiency lies in intelligent systems that autonomously optimize performance based on a multitude of variables.

- AI-Powered Temperature Management: Next-generation refrigeration controllers leverage Artificial Intelligence (AI) and machine learning algorithms. They go beyond simple setpoints, continuously analyzing internal cargo temperature trends, external ambient conditions (temperature, humidity, solar load), door events, journey duration, and even the specific thermal characteristics of the cargo itself. The system then proactively adjusts cooling parameters, defrost cycles, and fan speeds with unprecedented precision, ensuring optimal product quality with the absolute minimum energy expenditure. These systems learn and adapt over time, becoming more efficient with each journey.

- Automated Loading/Unloading & Pre-Cooling Sequences: Integration with warehouse management systems allows for automated pre-cooling sequences initiated remotely before arrival. Smart systems can also optimize dock procedures, potentially coordinating with automated loading/unloading equipment to minimize door-open time and precisely manage the thermal influx during cargo transfer, maintaining the cold chain integrity more efficiently than manual processes.

Integration is Imperative: Holistic Solutions & Expert Partnerships

Achieving maximum refrigerated truck efficiency isn’t about bolting on a single gadget; it demands a holistic view of the entire cold chain vehicle as an integrated system. Each upgrade interacts with others – advanced insulation reduces the load on the refrigeration unit, which, when equipped with variable speed tech, consumes less power, which is partially supplied by solar panels, all monitored and optimized by AI. The weight savings from VIP insulation might allow for a slightly larger battery pack enabling longer electric standby times. Success hinges on careful planning, system compatibility, and understanding the specific operational profile (long-haul, multi-stop urban delivery, high-value pharmaceuticals). This complexity underscores the critical importance of partnering with experienced specialists in refrigerated body design and integration, such as Vantrucktrailer. Their expertise spans selecting the optimal chassis (be it a nimble van truck for local deliveries, a versatile cargo truck for regional distribution, or a large semi-trailer), specifying compatible cutting-edge components, ensuring structural integrity with added equipment weight, and seamlessly integrating telematics, power systems, and controls into a unified, high-efficiency platform tailored precisely to the unique demands of your perishable cargo and operational routes. This collaborative, system-wide approach unlocks the full potential of modern technology, transforming refrigerated transport into a model of efficiency, reliability, and sustainability.