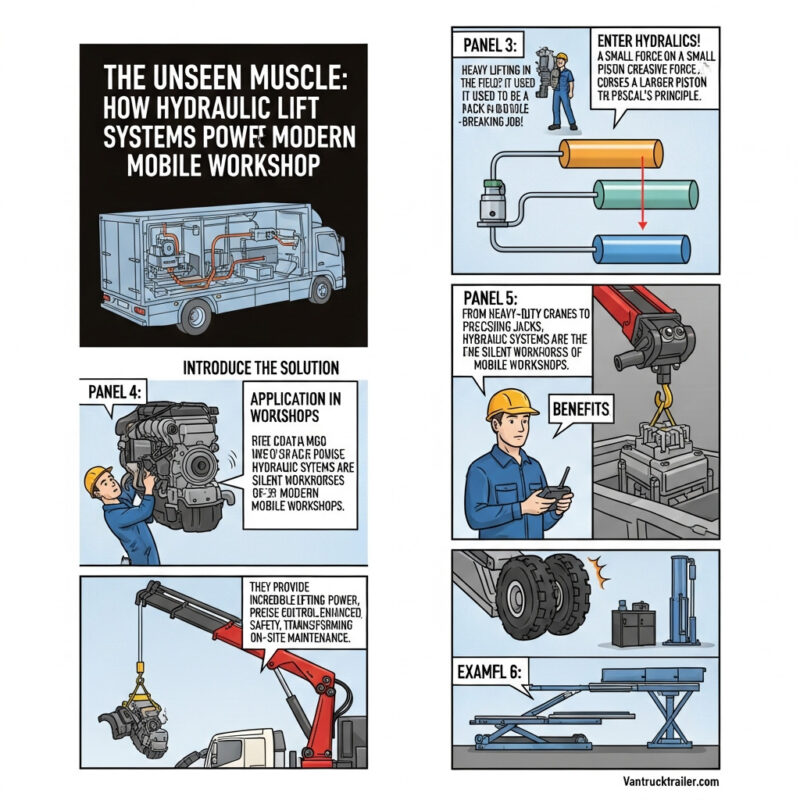

In the relentless pursuit of efficiency within field service operations, where every minute saved translates directly to increased capacity and customer satisfaction, the mobile workshop truck stands as a pinnacle of logistical and technical ingenuity. While tool organization, power systems, and climate control are vital components, one element often operates silently in the background, yet fundamentally transforms the vehicle’s capabilities: the hydraulic lift system. Far more than a simple convenience, strategically integrated hydraulic lifting mechanisms – be they integrated platform lifts, crane arms, scissor lifts, or even elevating workbenches – serve as the indispensable musculoskeletal framework upon which the productivity, safety, and sheer practicality of a high-performance mobile workshop are built. They tackle the fundamental physical challenges inherent in field service: moving substantial weight, accessing awkward spaces, and enabling precision work without backbreaking strain. Neglecting this critical component during mobile workshop customization risks creating a beautifully equipped box that remains fundamentally limited by the physical constraints of manual handling, ultimately hindering technician productivity, increasing job site risks, and capping the potential return on this significant operational investment. Understanding the multifaceted significance of these systems is paramount for any business serious about maximizing their mobile operational potential.

The Foundation of Fluid Power: Why Hydraulics Reign Supreme

Before delving into applications, it’s crucial to grasp why hydraulic lift systems are uniquely suited to the demanding environment of a mobile workshop. Hydraulic power operates on the principle of transmitting force through an incompressible fluid, typically oil. This fundamental characteristic delivers unparalleled advantages over purely mechanical or electrical alternatives:

- Exceptional Power Density: Hydraulic cylinders generate immense force from relatively compact components. A modestly sized hydraulic pump and cylinder can effortlessly lift loads of several hundred kilograms or more – loads that would require vastly larger, heavier, and more cumbersome electric motors or complex mechanical gearing systems. This high power-to-size ratio is absolutely critical within the spatially constrained confines of a mobile workshop truck, where every cubic centimeter must be optimally utilized.

- Precise Control and Smooth Operation: Hydraulic systems offer exceptional control over speed and movement. Flow control valves enable operators to precisely regulate the extension and retraction speed of lifts or cranes, allowing for gentle placement of delicate equipment or controlled lowering of heavy components. This controlled motion is essential for preventing damage to expensive assets, ensuring workshop safety during load handling, and facilitating delicate alignment tasks that would be impossible with jerky mechanical systems.

- Robustness and Reliability: Engineered hydraulic components are inherently robust, designed to withstand high pressures, shock loads, vibrations encountered during transit, and exposure to harsh environmental elements like dust, moisture, and temperature extremes common on job sites. When properly maintained, hydraulic systems deliver exceptionally long service life and dependable performance even under continuous, heavy-duty use cycles, minimizing costly downtime for repairs that plague less durable solutions.

Unlocking Operational Efficiency: Productivity Gains Quantified

The most immediate and tangible impact of integrated lifts is a dramatic surge in technician productivity. By systematically reducing or eliminating manual handling burdens, lifts fundamentally reshape the workflow:

- Drastic Reduction in Manual Handling Time: Loading and unloading heavy equipment, parts, or toolkits becomes a task measured in seconds rather than minutes or hours spent wrestling with ramps, dollies, or relying solely on brute strength. Integrated platform lifts or crane arms allow technicians to transfer loads directly from ground level into the workshop bay or onto a waiting cart with minimal effort, significantly accelerating site arrival readiness and job completion times.

- Minimized Physical Fatigue: Constantly lifting heavy objects, bending, twisting, and straining takes a severe toll on the human body. Hydraulic lifts shoulder this burden, preserving technician energy and focus for the skilled diagnostic and repair tasks that truly add value. This reduction in physical exertion directly translates to sustained higher output levels throughout the workday, fewer work-related injuries, and improved morale, contributing significantly to workforce sustainability.

- Optimized Workshop Flow: Strategic placement of lifts within the workspace eliminates bottlenecks. A hydraulic scissor lift table integrated into the main workbench area brings heavy components up to a comfortable ergonomic height for disassembly and repair, eliminating the need to crouch on the ground or awkwardly manhandle engines or transmissions. This ergonomic workflow ensures tools and parts are readily accessible at the optimal working height, streamlining every step of the repair process.

Elevating Safety: Mitigating Critical Job Site Hazards

Beyond productivity, hydraulic lift systems are paramount investments in workshop safety, addressing some of the most persistent and high-risk hazards faced by field technicians:

- Eliminating Manual Lifting Injuries: Musculoskeletal disorders (MSDs) – strains, sprains, and back injuries – remain among the most common and costly workplace injuries, particularly in mechanical trades. Hydraulic lifts virtually eliminate the need for dangerous manual lifting of heavy or awkward loads, providing a mechanical advantage that safeguards technicians’ long-term health and reduces costly workers’ compensation claims and lost workdays.

- Secured Load Handling: Integrated cranes and lifting arms equipped with appropriate slings, hooks, or specialized attachments provide secure control over suspended loads. This prevents components from slipping, falling, or swinging uncontrollably during transfer, mitigating the risk of crush injuries, impact damage to vehicles or equipment, or injuries to personnel working nearby. The inherent stability and control of hydraulic systems are far superior to manual methods or less stable alternatives.

- Enhanced Access and Stability: For tasks requiring work underneath vehicles or machinery, mobile column lifts or scissor lifts provide a stable, elevated platform far safer than crawling under a vehicle supported only by jack stands on potentially uneven ground. This secure access significantly reduces the risk of catastrophic crush injuries. Similarly, elevated platforms offer safer access to high components on machinery or within the workshop bay itself, replacing precarious ladder use.

Versatility Amplified: Adapting to Diverse Service Demands

The true power of hydraulic lift systems lies in their inherent versatility. Modern solutions can be tailored to suit a vast array of applications beyond simple loading:

- Integrated Work Platforms: Hydraulic platform lifts integrated into the rear or side of the workshop body serve dual purposes: loading/unloading and providing a stable, elevated work platform for tasks like equipment calibration, testing, or even acting as a small mobile stage truck platform for presentations in industrial settings.

- Compact Crane Arms: Articulating hydraulic crane arms mounted internally or externally offer unparalleled flexibility for retrieving tools or parts from deep within the workshop, lifting equipment over obstacles, or positioning heavy components precisely onto a workbench or repair stand.

- Scissor Lift Tables: These provide vertical adjustment within the workshop bay, transforming a standard bench into an ergonomic workstation adaptable for different tasks and user heights, or serving as a dedicated station for component disassembly and rebuild.

- Specialized Component Lifts: Dedicated hydraulic lifts designed for specific tasks, like lifting heavy vehicle tires, batteries, or transmissions directly onto work surfaces, further streamline niche workflows inherent in mobile repair trucks servicing diverse industries.

Specialized Applications: Hydraulics Enabling Niche Excellence

In certain high-demand sectors, hydraulic lifts transition from beneficial to absolutely critical, enabling unique operational models:

- Mobile Stage & Event Support Trucks: For the mobile stage truck, hydraulic systems are the literal backbone. Hydraulic leveling jacks provide critical stabilization on uneven ground. Powerful hydraulic lift gates are essential for loading heavy trussing, LED truck lighting fixtures, and audio racks. Some advanced systems incorporate hydraulic stage deck lifts or even telescopic towers with integrated lifting points for rigging, transforming the vehicle into a self-contained deployment platform crucial for rapid, safe event setup and teardown.

- Heavy-Duty Industrial Solutions: Workshops servicing mining, construction, or agriculture demand extreme lifting capabilities. Heavy-duty hydraulic cranes capable of handling multi-ton components, robust scissor lifts for accessing large machinery, and specialized material handling lifts are non-negotiable. Durability and capacity become the primary drivers, ensuring the mobile workshop can handle the immense weights encountered in these sectors safely and efficiently.

Integration Imperative: Designing Hydraulics into the Workshop Ecosystem

Successfully harnessing hydraulic power requires thoughtful integration during the mobile workshop customization phase:

- Chassis and Structural Considerations: Hydraulic systems impose significant weight and require robust mounting points. Selecting a chassis with adequate payload capacity (GVWR) and reinforcing the workshop body structure at lift mounting locations is essential for structural integrity and long-term reliability. Location must balance accessibility, weight distribution, and avoiding interference with other critical systems.

- Power System Synergy: Hydraulic pumps require substantial power. Integrating a sufficiently sized power generation system – encompassing high-output alternators, large auxiliary battery banks, and potentially a diesel generator – is mandatory to drive hydraulic pumps without draining vehicle starting batteries or compromising other workshop functions.

- Ergonomic Control Placement: Operator controls must be intuitively placed, easily accessible, and designed for safe operation – often requiring controls at both the lift and a remote location for optimal visibility. Clear safety interlocks and emergency stop functions are non-negotiable components of the hydraulic control system.

Future-Proofing through Fluid Power: The Strategic Investment

Viewing hydraulic lift systems solely as an equipment cost is a profound strategic error. Their implementation represents a fundamental investment in the core capabilities and future resilience of the field service operation:

- Scalability and Adaptability: A well-designed hydraulic system provides a foundational capability that can be adapted as service offerings evolve. Adding different attachments or upgrading components can extend functionality without replacing the core system.

- Enabling New Service Offerings: The presence of significant lifting capacity can open doors to service contracts previously deemed impractical for a mobile unit – such as handling large industrial components or complex installations – directly contributing to business growth and diversification.

- Partnering for Expertise: Given the critical nature of design and integration, partnering with experienced mobile workshop builders like Vantrucktrailer is essential. Their expertise in chassis selection, structural engineering, hydraulic system sizing, component selection (pumps, valves, cylinders, reservoirs), and regulatory compliance ensures a seamless, safe, and optimized installation. They understand the intricate balance between payload, power requirements, workspace layout, and the specific lifting demands of different trades, translating operational needs into a robust technical solution. This collaboration guarantees that the hydraulic lift system becomes a perfectly integrated, reliable, and powerful asset within the mobile ecosystem.

The integration of sophisticated hydraulic lift systems is no longer a luxury reserved for the largest fleets; it is a fundamental strategic imperative for any mobile workshop aiming to achieve peak efficiency, uncompromising safety, and true operational versatility. By transforming physical limitations into operational strengths, hydraulic power ensures that the modern mobile workshop truck is not just a vehicle carrying tools, but a fully capable, agile, and powerful extension of the service team, ready to conquer the toughest challenges on any job site.